CONCORD GROUP is a construction holding specializing in the implementation of investment projects for industrial construction in the metallurgy, coke making and power fields.

The Holding unites a number of specialized construction companies operating under common CONCORD GROUP brand.

Many years of experience allows us to offer effective solutions in the implementation of turnkey projects.

High quality and reliability of the work performed in accordance with current international standards is our priority.

COMPANY'S PRINCIPLES

The basis of the activity of CONCORD GROUP lies in effective integration of engineering knowledge, advanced technologies, professional specialists and technical resources into a single organizational structure. CONCORD GROUP supports the corporate ideology of customer orientation, actively strives for mutually beneficial cooperation with partners with a priority on ensuring the impeccable quality of services.

We strive for continuous improvement of the quality management system and ensuring the requirements of international standards, which in turn leads to improved quality and increased competitiveness.

The principle of CONCORD GROUP related to provision of services is unconditional compliance with the requirements of the current legislation, international agreements, industry and corporate standards.

Concord Engineering brings together a number of specialized construction companies operating under common CONCORD GROUP brand.

Management of EPC projects in the energy sector, including procurement, order placement, logistics and supply management, quality control of supplied products, all construction, installation and commissioning works.

Code of company: 45720999

Ukraine, 52064, Dnipropetrovska oblast, Dniprovskyi district, Sursko-Lytovske village (N), 1K Nova str.

Phone: +38(096)-660-88-17,

E-mail address: koc@concordgroup.com.ua

Specialized engineering company that performs commissioning and technological control in the coke-chemical industry and carries out research and development work on coke ovens.

EPC project management, including procurement, order placement, logistics and supply management, quality control of supplied products.

EPC project management, including procurement, order placement, logistics and supply management, quality control of supplied products.

Personnel is one of the most important success factors for CONCORD GROUP. The Group’s HR strategy is based on the principles of long-term cooperation, mutual respect and continuous development.

Continuous professional development and personal self-improvement will allow each of the employees to make the best use of their individual qualities and all available potential.

Through practical on-the-job training on one hand and intensive theoretical training on the other, CONCORD GROUP gives employees the opportunity to gain valuable professional experience.

2001

Foundation of EPC services business for coke making plant under CONCORD GROUP brand.

2002

Start of the first EPC project related to the reconstruction of coke oven battery No. 3 at the Dunaferr steel plant (Hungary). The project was successfully completed in 2005 and led to the establishment of a long-term cooperation with the customer. This project also marked the beginning of the strategic partnership with the state institute Giprokoks (Ukraine), one of the world’s largest companies in the design of coke industry plants.

2003

The second big order for the reconstruction of coke oven battery No. 3 for Kremikovtzi AD, the largest metallurgical company in Bulgaria. This project was followed by a number of others related to complex repairs and the supply of refractories for coke oven batteries No. 3, 4. As a result of this project, which was completed in 2005, CONCORD GROUP brand strengthened its position in the Central European market.

2006

A contract was signed for the construction of a new coke battery No. 1-bis at Radlin coke making plant for Zabrze by-product coke plant (Poland). The contract was accompanied by additional orders for the supply of refractory materials. This project enabled the Group to establish itself as a global provider of EPC services to the coke industry. Concord Steel General Trading FZC (UAE) was established and assumed the functions of the financial center of the Group.

2007

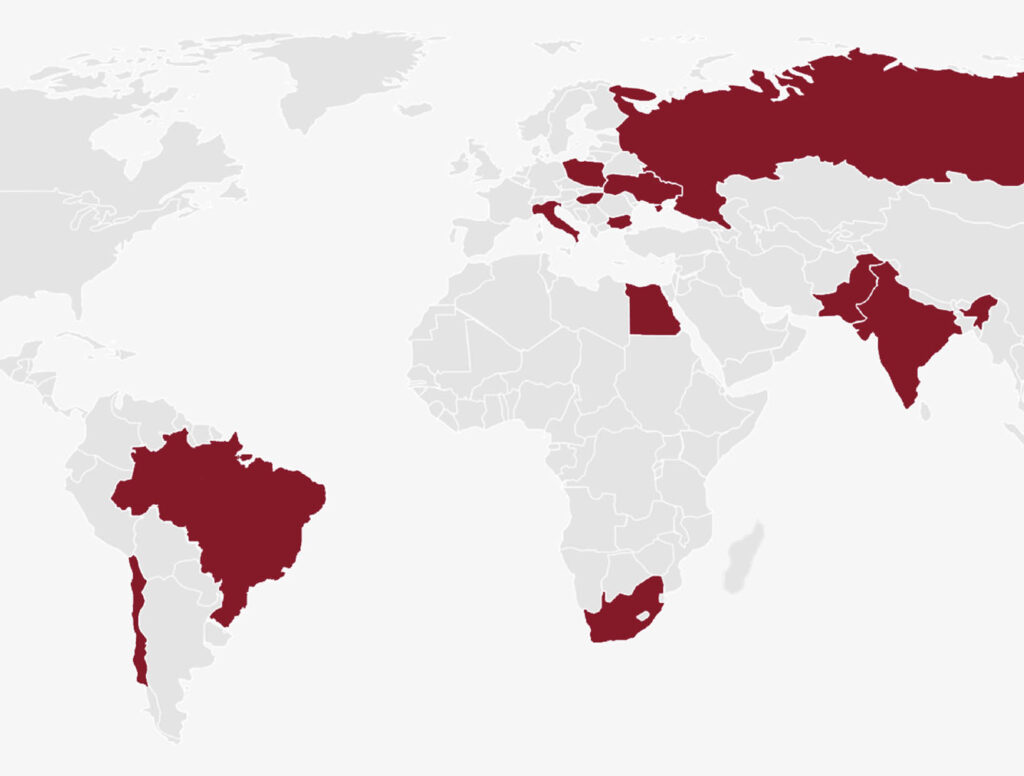

In January, the Group entered the Asian market by winning a turnkey contract for revamping coke oven batteries No. 1, 2 for Pakistan Steel Mills Corporation, the leading state-owned producer of long products and high-strength iron products in Pakistan.

In April, Concord Steel Pakistan was established to support work under the Pakistan Steel Mills contract.

In February, the Ukrainian company SIE MAK LLC joined the CONCORD GROUP. As a result, CONCORD GROUP has expanded the range of services by the innovative technology of ceramic welding of coke oven brickwork under the conditions of operating plant. SIE MAK LLC strengthened the Group’s internal competencies and increased the diversification of its business segments.

In September, the Group won a tender for the turnkey reconstruction of coke oven battery No. 4 at Isdemir Steel Plant (Turkey). In October, the Group successfully entered the Indian market by signing a contract for the supply of refractory materials for the construction of coke oven battery No. 2 at the SAIL/IISCo steel plant (India).

2008

In October, the Group signed its largest contract for the reconstruction of coke oven batteries No. 3 and No. 4 for USIMINAS, one of the leading steel producers in Brazil. Cooperation with a leading company in the steel sector of the largest economy in Latin America has become another milestone on the way to establishing CONCORD GROUP in the world market.

2009

In December, Giprokoks Polska (Poland) was established to increase the internal engineering potential. Giprokoks Polska was established jointly with the State Institute Giprokoks (Ukraine) as an internal engineering division of the Group.

2010

In January, Koksokhimremont LLC joined the CONCORD GROUP. LLC Koksokhimremont is the successor of the Soviet enterprise and has more than forty years of experience in the field of repair and construction services for coke making plants. For decades, Koksokhimremont was an in-house company servicing the coke ovens of the Kryvorizhstal metallurgical plant (now ArcelorMittal Kryvyi Rih, Ukraine).

In order to further advance to the world markets, in July Concord Engineering GmbH (Vienna, Austria) which acts as a managing company was founded.

2012

In June, the process of merging the companies into a single Concord Engineering holding was completed.

2014

Group companies signed contracts with ARCELORMITTAL KRIVIY RIH to perform work for coke oven batteries No. 5, 6 complex. The construction facilities have been put into operation, which allows us to proudly include this project in the track record of ConcordGroup.

Integrated EPC services are the key business segment of CONCORD GROUP. Although, the companies of the Group may act as subcontractors, performing certain types of work and services.